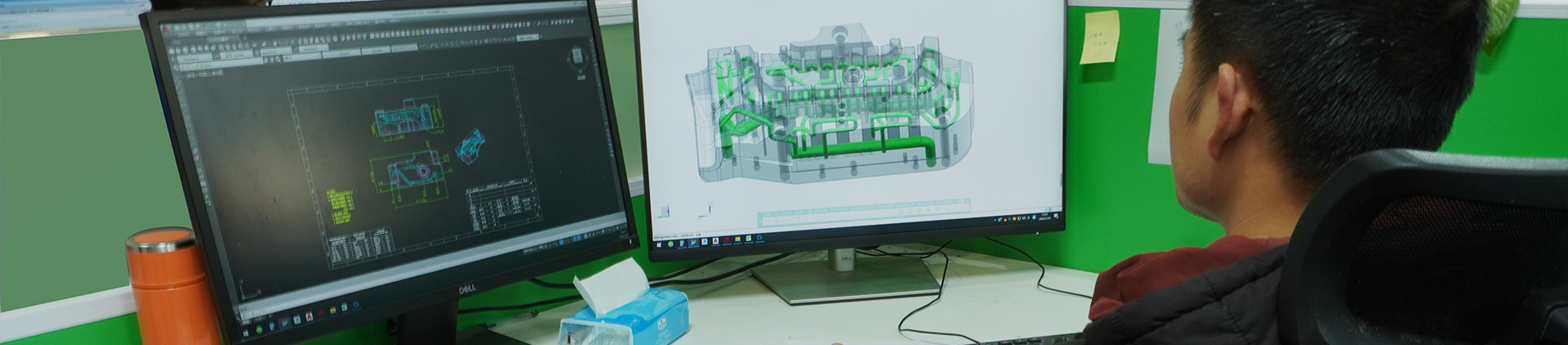

Careful Design

The 3D conformal waterway is significantly different from the traditional 2D waterway. Its biggest advantage is that it can ensure that the mold waterway is closer to the product cavity surface. This design can not only maintain a balanced mold temperature and thereby improve product yield, but also improve heat exchange efficiency, shorten the molding cycle of injection molding and die-casting, and thereby reduce production costs.

For the small features and thin-walled structures of the mold, traditional manufacturing and ordinary 3D printing cannot add water channels. Through the joint innovation of "design-material-process", LAMOTEK has designed an extremely thin waterway with a wall thickness limit of 0.7 mm and a minimum waterway diameter of 1 mm. This ultra-fine conformal water path achieves precise cooling, thereby shortening the production cycle and improving product quality.

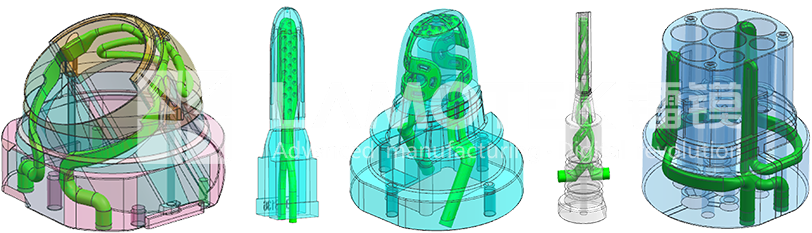

Following waterway diagram

3D printing can effectively improve the problem of trapped air. LAMOTEK has accumulated many years of experience in exhaust design, established mature model design standards and has a large number of successful application cases. At present, our technology can realize a multi-stage and multi-angle exhaust structure according to actual working conditions, taking into account the balance between exhaust effect and mold strength.

Integrated multi-sided exhaust video

The manufacturing concept of 3D printing based on "additive" completely breaks away from the constraints of traditional processing methods. The only limitation on innovation is based on traditional design thinking. Without considering design constraints, designers can use topology optimization and simulation to carry out disruptive innovations in product structure to achieve lightweight or special functional designs. LAMOTEK combines 3D printing technology with topology optimization and simulation technology to provide customers with more creative design solutions. In the future, we will also actively apply generative design methods to further leverage the value of 3D printing technology.

Generative design drawing