LAMOTEK Insights | How Metal 3D Printing Supports Daily Chemical Packaging: Technological Innovation and Economic Benefits

The Role of Packaging in the Daily Chemical Industry

In our daily lives, packaging plays a crucial role. Whether it's a bottle of drink or a jar of eye cream, packaging serves an essential function. It must protect the contents, ensure their chemical stability, and prevent adverse reactions with the packaging material. Additionally, packaging should be user-friendly and align with consumer habits. For daily chemical packaging, functionality and aesthetics must go hand in hand, offering a positive user experience while visually attracting customers.

The main forms of daily chemical packaging include plastic bottles, cartons, tubes, and glass containers. Plastic bottles, known for their durability, are widely used and typically produced through injection molding or blow molding. Before mass-producing plastic packaging, 3D printing technology is often used to quickly produce prototypes and validate design ideas. Therefore, when people think of 3D printing, they often associate it with the development of plastic prototypes.

Metal 3D Printing: Enhancing Mold Design Flexibility and Production Efficiency

With advancements in technology, 3D printing in the daily chemical packaging industry is no longer limited to plastic prototypes but has extended to mass production. It has found mature applications in metal molds, demonstrating great potential in the mold manufacturing stage.

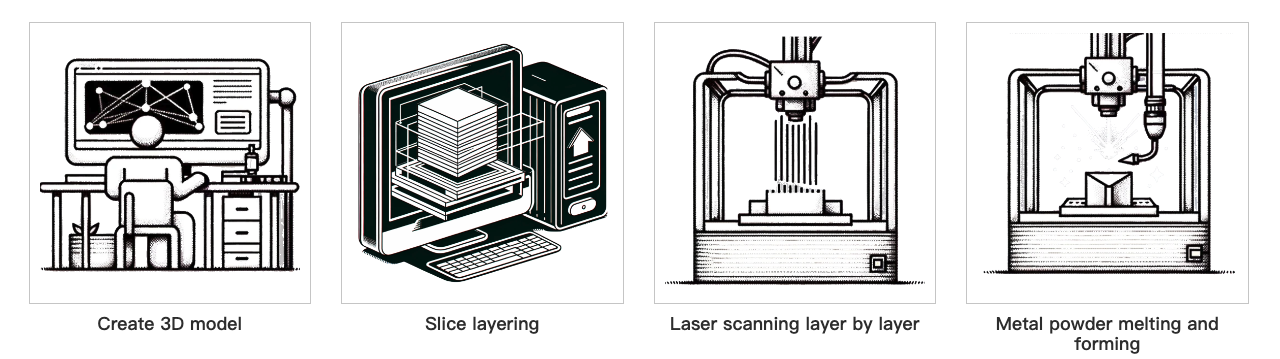

Currently, mold production is generally achieved by milling blocks of metal into the desired shape, which can present challenges when processing complex surfaces or deep areas. In contrast, metal 3D printing offers greater design freedom. By layer-by-layer melting of metal powder, it precisely builds the required shape, making it possible to achieve intricate structures.

Metal 3D Printing (SLM) Schematic Diagram

The cooling system of a mold significantly affects the injection molding time, product dimensions, and surface quality. Traditional machining methods struggle to create complex, curved cooling channels, and common channels are typically straight, which limits cooling in deep cavities and narrow areas. This can hinder precise temperature control, negatively impacting both the injection cycle and product yield. Metal 3D printing, however, can easily create complex conformal cooling channels, enabling more accurate temperature control of the mold. This improves surface quality, increases product yield, shortens injection cycles, and significantly boosts production efficiency.

Case Study Diagram

Take the example of the cosmetic bottle cavity insert shown in the diagram. By using 3D printing technology, the mold achieved more precise temperature control and faster cooling. The local hot spot temperature was reduced by 43°C, and the injection cycle improved by 38%. Additionally, due to uniform cooling, the surface quality of the injected product was significantly enhanced.

LAMOTEK: Committed to Advancing Technology and the Mold Industry

Metal 3D-printed molds not only enhance the production yield of complex or high-demand injection products but also significantly shorten the injection cycle and improve production efficiency. LAMOTEK has been deeply involved in the metal 3D-printed mold sector for over a decade, continuously striving to enhance customer profitability. With a wealth of technical and industry experience, we have successfully provided metal 3D-printed molds to numerous customers in the daily chemical packaging industry, delivering remarkable benefits to them.

Looking ahead, LAMOTEK will continue its efforts to advance technology and the mold industry, working together with industry partners to drive innovation and growth!